Iibholiti zeHexagon zenziwe kwiDIN 931

| Igama lemveliso | I-HEX BOLT DIN 931 / ISO4014 isiqingatha sentambo |

| Umgangatho | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| IBanga | IBanga leNsimbi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; I-ASTM: 307A, A325,A490, |

| Ukugqiba | IZinc(Mthubi,Mhlophe,Bhulowu,Mnyama),Hop Dip iGalvanized(HDG),Black oxide, I-Geomet, iDacroment, i-anodization, i-Nickel efakwe i-Zinc-Nickel |

| Inkqubo yeMveliso | I-M2-M24: I-Froging ebandayo, i-M24-M100 i-Hot Forging, Umatshini kunye ne-CNC yokuqhotyosha okuLungisiweyo |

| Iimveliso ezenzelwe ixesha lokukhokela | 30-60 iintsuku, |

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | I-pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| IBanga A | imiz | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| IBanga B | imiz | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | IBanga A | imiz | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| IBanga B | imiz | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | IBanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| IBanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Ubungakanani bobizo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| IBanga A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| IBanga B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | IBanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| IBanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| IBanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| IBanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | I-pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| IBanga A | imiz | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| IBanga B | imiz | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | IBanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| IBanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | IBanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| IBanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Ubungakanani bobizo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| IBanga A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| IBanga B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | IBanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| IBanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| IBanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| IBanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | I-pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Ubungakanani bobizo | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| IBanga A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| imiz | - | - | - | - | - | - |

|

|

|

|

|

| ||

| IBanga B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | ubuninzi=ubungakanani obuqhelekileyo | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Ubude boMsonto b | - | - | - | - | - | - |

|

|

|

|

| |||

Iimpawu kunye neeNzuzo

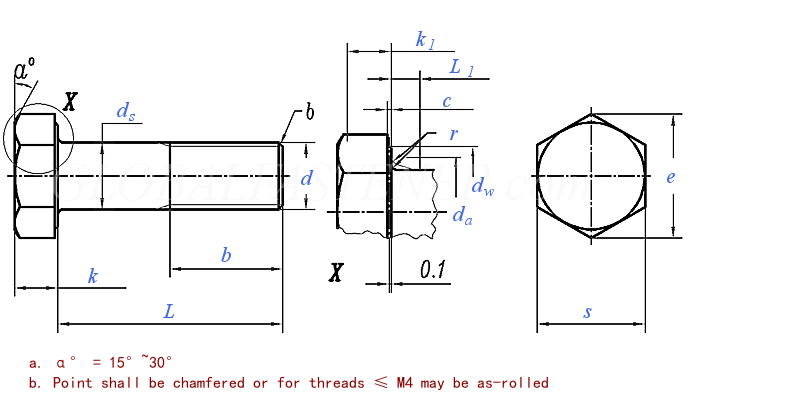

Iibholiti ezinehexagon luhlobo lwesibophelelo esiyilwe sinentloko enamacala amathandathu kunye neshafti enemisonto engaphelelanga. I-DIN 931 ngumgangatho wobugcisa ochaza iimfuno zokwenziwa kweebholithi ezinehexagon. Ezi bholithi ziqhele ukusetyenziswa kwimizi-mveliso eyahlukeneyo kunye nezicelo zoomatshini ngenxa yamandla azo, ukuqina, kunye nokuguquguquka.

Enye yezinto eziphambili zeebholiti ze-hexagon ezenziwe kwi-DIN 931 kukuculwa kwazo ngokuyinxenye. Ngokungafaniyo neebholithi ezithungelwe ngokupheleleyo, ezinemisonto ebaleka bonke ubude beshafti, iibholiti ezinehexagon zinemisonto kuphela kwinxalenye yobude bazo. Olu luyilo luvumela ukuba ibholithi ibotshelelwe ngokukhuselekileyo endaweni ngelixa isabonelela ngokucocwa okwaneleyo kumacandelo ukuba ahambe xa kukho imfuneko.

Omnye umba obalulekileyo weebholiti zehexagon yintloko yazo enamacala amathandathu. Olu luyilo lubonelela ngeenzuzo ezininzi ngaphezu kwezinye iintlobo zeebholiti. Okokuqala, imilo ye-hexagonal ivumela ukuqina lula kunye nokukhulula nge-wrench okanye i-socket. Okwesibini, indawo enkulu yendawo yentloko isasaza amandla okuqinisa kwindawo ebanzi, ukunciphisa amathuba okulimala okanye ukuguqulwa.

Iibholiti zeHexagon ezenziwe kwi-DIN 931 ziyafumaneka kuluhlu olubanzi lobungakanani kunye nemathiriyeli, ezenza zilungele uthotho lwezicelo. Ziqhele ukusetyenziswa kulwakhiwo, iimoto, kunye noomatshini bemizi-mveliso, kunye nakwiiprojekthi zendlu kunye ne-DIY. Indibaniselwano yamandla azo, ukuqina, kunye nokulula kokusetyenziswa kwenza iibholithi zehexagon zibe yinxalenye ebalulekileyo kwiindidi ezininzi zoomatshini kunye nezixhobo.

Isishwankathelo, iibholiti ze-hexagon ezidalwe kwi-DIN 931 zenzelwe ukubonelela ngesisombululo esikhuselekileyo nesithembekileyo sokuqina kwezicelo ezahlukeneyo. Ishafti yabo enemisonto engaphelelanga kunye nentloko enamacala amathandathu ibonelela ngoluhlu lwezibonelelo, kubandakanya lula ukusetyenziswa, ukomelela okongeziweyo kunye nokuqina, kunye nokuguquguquka. Ezi bholithi ziyinxalenye ebalulekileyo yeentlobo ezininzi zoomatshini kunye nezixhobo, kwaye ukuthandwa kwazo kububungqina bomgangatho kunye nokusebenza kwazo.