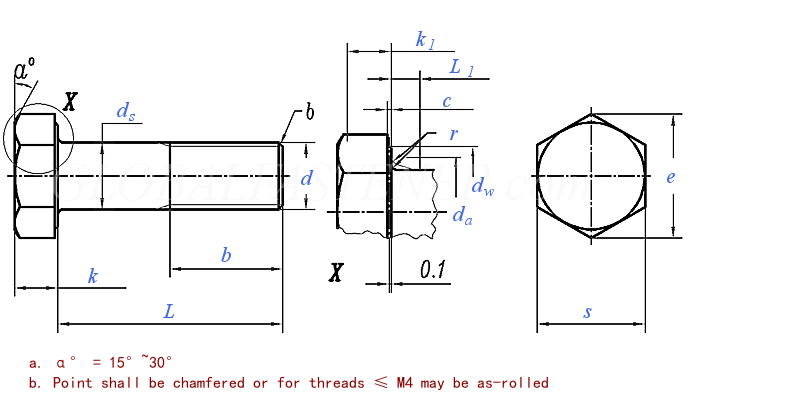

Hex Bolt Din 931/iso4014 Umsonto wesiqingatha

| Igama lemveliso | I-HEX BOLT DIN 931 / ISO4014 isiqingatha sentambo |

| Umgangatho | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| IBanga | IBanga leNsimbi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; I-ASTM: 307A, A325,A490, |

| Ukugqiba | IZinc(Mthubi,Mhlophe,Bhulowu,Mnyama),Hop Dip iGalvanized(HDG),Black oxide, I-Geomet, iDacroment, i-anodization, i-Nickel efakwe i-Zinc-Nickel |

| Inkqubo yeMveliso | I-M2-M24: I-Froging ebandayo, i-M24-M100 i-Hot Forging, Umatshini kunye ne-CNC yokuqhotyosha okuLungisiweyo |

| Iimveliso ezenzelwe ixesha lokukhokela | 30-60 iintsuku, |

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | I-pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| IBanga A | imiz | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| IBanga B | imiz | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | IBanga A | imiz | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| IBanga B | imiz | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | IBanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| IBanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Ubungakanani bobizo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| IBanga A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| IBanga B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | IBanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| IBanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| IBanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| IBanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | I-pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| IBanga A | imiz | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| IBanga B | imiz | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | IBanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| IBanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | IBanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| IBanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Ubungakanani bobizo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| IBanga A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| IBanga B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | IBanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| IBanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| IBanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| IBanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | I-pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Ubungakanani bobizo | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| IBanga A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| imiz | - | - | - | - | - | - |

|

|

|

|

|

| ||

| IBanga B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | ubuninzi=ubungakanani obuqhelekileyo | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Ubude boMsonto b | - | - | - | - | - | - |

|

|

|

|

| |||

Iimpawu kunye neeNzuzo

Iibholiti zeHex, ezikwabizwa ngokuba ziihexagon head bolts, ziqhele ukusetyenziswa kwiziqhoboshi kwizicelo ezahlukeneyo. I-Half Thread Hex Bolt Din 931 / iso4014 yi-fastener ephezulu ehambelana nemigangatho ye-DIN 931 / ISO 4014. Le bolt inentloko ene-hexagonal kunye ne-shank ene-threaded ngokuyinxenye, enika amandla okubamba aphezulu kunye nokumelana okugqwesileyo kwi-deformation kunye nokungcangcazela.

I-Half Thread Hex Bolt Din 931 / iso4014 yenziwe ngezinto ezikumgangatho ophezulu, ezifana ne-carbon steel, i-alloy steel, kunye nensimbi engenasici. I-carbon steel kunye ne-alloy steel grade zinika amandla abalaseleyo kunye nokuqina, ngelixa amabakala ensimbi engenasici anikezela ukuxhathisa okuphezulu kwe-corrosion kwiindawo ezinzima. Ezi bholiti zifumaneka ngobukhulu obahlukeneyo kunye nokugqiba, njengethafa, i-zinc-plated, kunye ne-oxide emnyama egqunywe, ukuhlangabezana neemfuno ezahlukeneyo zesicelo.

IHalf Thread Hex Bolt Din 931/iso4014 iqhele ukusetyenziswa koomatshini, iimoto, ulwakhiwo, kunye namanye amashishini. Ifanelekile kwizicelo ezifuna ukuqiniswa okuchanekileyo okuphezulu, njengamacandelo e-injini, uqhagamshelo lwesakhiwo, kunye neendibano zoomatshini. Le bolt nayo ilula ukuyifaka kwaye ifuna ukugcinwa okuncinci, oko kuyenza ibe sisisombululo esineendleko eziphezulu kwizicelo ezininzi.

Ukuqukumbela, iHalf Thread Hex Bolt Din 931/iso4014 yinto ethembekileyo neguquguqukayo yokuqinisa enika amandla aphezulu, ukuqina, kunye nokumelana nokubola. Nokuba ufuna into yokubopha koomatshini bakho okanye iprojekthi yokwakha, okanye ufuna icandelo elichanekileyo eliphezulu kwisicelo sakho semoto, le bolt lolona khetho lubalaseleyo. Qhagamshelana nathi namhlanje ukuze ufunde ngakumbi malunga neHalf Thread Hex Bolt Din 931/iso4014 kunye nezinye izisombululo zokuqinisa.