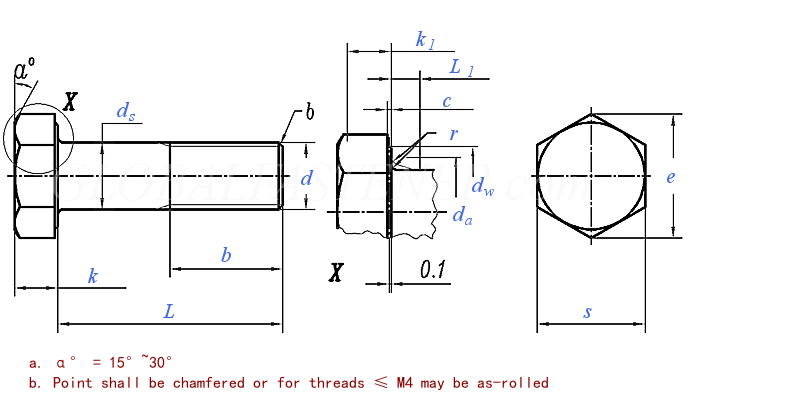

Hex Bolt Din 931 / iso4014 933 / iso4017 Grade10.9

| Igama lemveliso | I-HEX BOLT DIN 931 / ISO4014 isiqingatha sentambo |

| Umgangatho | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| IBanga | IBanga leNsimbi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; I-ASTM: 307A, A325,A490, |

| Ukugqiba | IZinc(Mthubi,Mhlophe,Bhulowu,Mnyama),Hop Dip iGalvanized(HDG),Black oxide, I-Geomet, iDacroment, i-anodization, i-Nickel efakwe i-Zinc-Nickel |

| Inkqubo yeMveliso | I-M2-M24: I-Froging ebandayo, i-M24-M100 i-Hot Forging, Umatshini kunye ne-CNC yokuqhotyosha okuLungisiweyo |

| Iimveliso ezenzelwe ixesha lokukhokela | 30-60 iintsuku, |

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | I-pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| IBanga A | imiz | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| IBanga B | imiz | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | IBanga A | imiz | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| IBanga B | imiz | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | IBanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| IBanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Ubungakanani bobizo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| IBanga A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| IBanga B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | IBanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| IBanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| IBanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| IBanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | I-pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| IBanga A | imiz | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| IBanga B | imiz | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | IBanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| IBanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | IBanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| IBanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Ubungakanani bobizo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| IBanga A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| IBanga B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | IBanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| IBanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| IBanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| IBanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | I-pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Ubungakanani bobizo | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| IBanga A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| imiz | - | - | - | - | - | - |

|

|

|

|

|

| ||

| IBanga B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | ubuninzi=ubungakanani obuqhelekileyo | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Ubude boMsonto b | - | - | - | - | - | - |

|

|

|

|

| |||

Iimpawu kunye neeNzuzo

I-Hex Bolt Din 931 / iso4014 933 / iso4017 iBanga10.9 yimveliso ekumgangatho ophezulu eyenzelwe ukuhambisa ukusebenza okuphezulu. Ibakala layo le-10.9 liqinisekisa amandla ayo, okwenza ukuba kukhuthazwe kakhulu kwizicelo zemizi-mveliso. Le modeli ye-hex bolt iza kwiinketho ezintathu ezahlukeneyo ukuze ihambelane neemfuno ezahlukeneyo, kubandakanya Iso4014 933, Iso4017, kunye neDin 931.

Ukuhlelwa kwe-10.9 yale hex bolt iguqulela kukuqina kokuqina kwe-1000 N/mm² kunye noxinzelelo lwesivuno lwama-900 N/mm². Iimpawu zayo zamandla aphezulu ziyenza ibe yinto efanelekileyo kwizicelo ezifuna amandla okuthwala umthwalo ophezulu okanye ezo zibonakaliswe kumaqondo okushisa aphezulu, afana ne-automotive and petrochemical industry.

Le modeli ye-hex bolt yenziwe ukuhlangabezana nemigangatho yomgangatho we-Din 931, Iso4014 933, kunye ne-Iso4017. Oku kuthetha ukuba iphantsi koqwalaselo olungqongqo lomgangatho ukuqinisekisa ukuba iyahlangabezana nemigaqo engqongqo echazwe kule migangatho. Ukongeza, idlula kwinkqubo yokuqina ukunyusa iipropathi zayo zamandla ekusebenzeni okuphezulu.

I-Hex Bolt Din 931 / iso4014 933 / iso4017 iBakala10.9 yenziwe ngezinto ezikumgangatho ophezulu eziqinisekisa ukuba ziyakwazi ukumelana nokubola, i-oxidation, kunye nokuguga. Ubume bayo bobume bunokumelana nokusetyenziswa rhoqo kunye nokuvezwa kwiimeko ezinzima zokusingqongileyo ngaphandle kokufumana nawuphi na umonakalo.

Ukuqukumbela, i-Hex Bolt Din 931 / iso4014 933 / iso4017 iBanga10.9 yimveliso eyomeleleyo nethembekileyo eyenzelwe ngokukodwa ukusetyenziswa kwimizi-mveliso. Ukuhlelwa kwayo kwe-10.9, kunye nokubambelela kwimigangatho yomgangatho, kuyenza ibholithi ephezulu yokusebenza kunye neempawu zamandla aphezulu. Ukuqina kwayo kunye nokuchasana neemeko ezirhabaxa zokusingqongileyo kuyenza ibe lutyalo-mali olugqwesileyo kuso nasiphi na isicelo semizi-mveliso.