I-DIN 6921 iibholiti ze-flange zeClass 8.8 kunye ne-10.9

| Igama lemveliso | I-HEX BOLT DIN 931 / ISO4014 isiqingatha sentambo |

| Umgangatho | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| IBanga | IBanga leNsimbi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; I-ASTM: 307A, A325,A490, |

| Ukugqiba | IZinc(Mthubi,Mhlophe,Bhulowu,Mnyama),Hop Dip iGalvanized(HDG),Black oxide, I-Geomet, iDacroment, i-anodization, i-Nickel efakwe i-Zinc-Nickel |

| Inkqubo yeMveliso | I-M2-M24: I-Froging ebandayo, i-M24-M100 i-Hot Forging, Umatshini kunye ne-CNC yokuqhotyosha okuLungisiweyo |

| Iimveliso ezenzelwe ixesha lokukhokela | 30-60 iintsuku, |

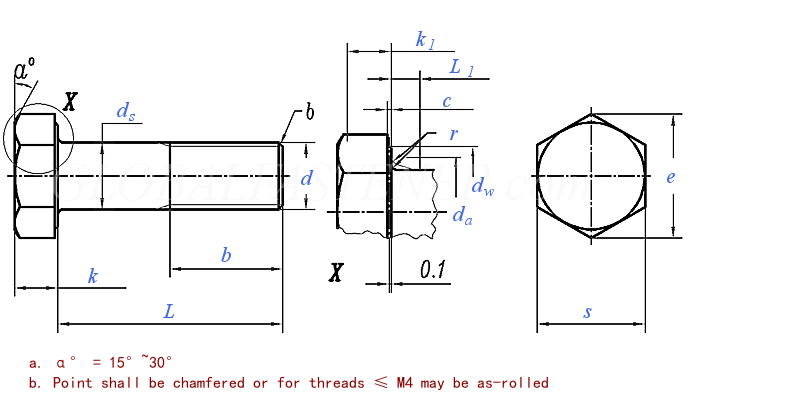

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | I-pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| IBanga A | imiz | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| IBanga B | imiz | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | IBanga A | imiz | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| IBanga B | imiz | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | IBanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| IBanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Ubungakanani bobizo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| IBanga A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| IBanga B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | IBanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| IBanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| IBanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| IBanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | I-pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| IBanga A | imiz | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| IBanga B | imiz | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | IBanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| IBanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | IBanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| IBanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Ubungakanani bobizo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| IBanga A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| IBanga B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | IBanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| IBanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| IBanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| IBanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | I-pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Ubungakanani bobizo | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| IBanga A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| imiz | - | - | - | - | - | - |

|

|

|

|

|

| ||

| IBanga B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | ubuninzi=ubungakanani obuqhelekileyo | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Ubude boMsonto b | - | - | - | - | - | - |

|

|

|

|

| |||

Iimpawu kunye neeNzuzo

I-DIN 6921 luhlobo lwe-hex flange bolt olusetyenziswa ngokuqhelekileyo kwimizi-mveliso kunye nezicelo zokwakha. Le bolt ineflange esebenza njengewasha eyakhelweyo kwaye inceda ukuhambisa umthwalo kwindawo ebanzi. Intloko yebholithi ine-hexagonal kwimilo kwaye kulula ukuyiqinisa usebenzisa i-wrench okanye i-socket.

Le bolt isetyenziswa kakhulu koomatshini, kumashishini eemoto, nakulwakhiwo, ngenxa yamandla ayo akhethekileyo kunye nokuqina. Yenziwe ngezinto ezikumgangatho ophezulu ezifana nentsimbi engatyiwayo, i-titanium, kunye nentsimbi ye-carbon, enika ukuxhathisa ixesha elide ngokuchasene nokuguga, ukubola kunye nokuhlwa.

Iibholiti ze-DIN 6921 zenziwe ngendlela yokunyamezelana kwaye ziphantsi kwemilinganiselo engqongqo yolawulo lomgangatho ukuqinisekisa ukuba ziyahlangabezana neyona migangatho iphezulu yomgangatho kunye nokusebenza. Ezi bholithi zifumaneka kuluhlu lobukhulu, ubude, kunye nokugqiba ukuze zihambelane nezicelo kunye neemfuno ezahlukeneyo.

Ukongeza, iibholiti ze-DIN 6921 zihambelana nemigangatho engqongqo yoshishino, kuquka iDIN (iDeutsches Institut für Normung) kunye nemigangatho ye-ISO (International Organisation for Standardization). Zikwavavanyelwa ukuqina kwazo, ukomelela kwazo, kunye nokuchaneka kobukhulu phambi kokuba zikhutshwe ukuze zithengiswe. Zonke ezi zinto zinegalelo kumgangatho obalaseleyo kunye nokusebenza okuthembekileyo kwe-DIN 6921 bolt.

Ngokubanzi, i-DIN 6921 bolt sisisombululo esiguquguqukayo nesiqinileyo esisetyenziswa kumashishini amaninzi ahlukeneyo. Yenzelwe ukunika amandla abalaseleyo okubamba, ukuxhathisa ukunxiba kunye nokukrazula, kunye nokulula kofakelo. Ulwakhiwo lwayo olukumgangatho ophezulu kunye nokubambelela ngokungqongqo kwimigangatho yeshishini kuyenza ibe lolona khetho luphezulu kwiinjineli, abaqulunqi, kunye neengcali zokwakha kwihlabathi liphela.