ICarbon Steel Hex Bolt Din 931/iso4014

| Igama lemveliso | I-CARBON STEEL HEX BOLT DIN 931/ISO4014 |

| Umgangatho | DIN,ASTM/ANSI JIS EN ISO,AS,GB |

| IBanga | IBanga leNsimbi: DIN: Gr.4.6,4.8,5.6,5.8,8.8,10.9,12.9; SAE: Gr.2,5,8; I-ASTM: 307A, A325,A490, |

| Ukugqiba | IZinc(Mthubi,Mhlophe,Bhulowu,Mnyama),Hop Dip iGalvanized(HDG),Black oxide, I-Geomet, iDacroment, i-anodization, i-Nickel efakwe i-Zinc-Nickel |

| Inkqubo yeMveliso | I-M2-M24: I-Froging ebandayo, i-M24-M100 i-Hot Forging, Umatshini kunye ne-CNC yokuqhotyosha okuLungisiweyo |

| Iimveliso ezenzelwe ixesha lokukhokela | 30-60 iintsuku, |

| Iisampulu zasimahla zesiqhoboshi esisemgangathweni | |

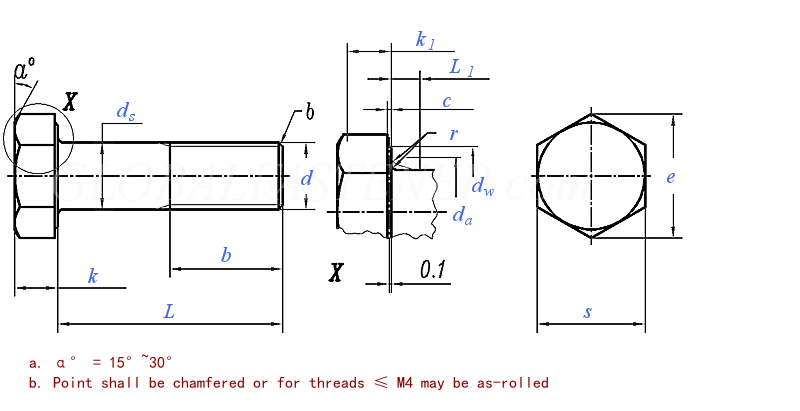

| Screw Thread | M1.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | (M7) | M8 | M10 | M12 | ||

| P | I-pitch | 0.35 | 0.4 | 0.45 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1 | 1.25 | 1.5 | 1.75 | |

| b | L≤125 | 9 | 10 | 11 | 12 | 13 | 14 | 16 | 18 | 20 | 22 | 26 | 30 | |

| 125<L≤200 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 26 | 28 | 32 | 36 | ||

| L>200 | 28 | 29 | 30 | 31 | 32 | 33 | 35 | 37 | 39 | 41 | 45 | 49 | ||

| c | max | 0.25 | 0.25 | 0.25 | 0.4 | 0.4 | 0.4 | 0.5 | 0.5 | 0.6 | 0.6 | 0.6 | 0.6 | |

| imiz | 0.1 | 0.1 | 0.1 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | 0.15 | ||

| da | max | 2 | 2.6 | 3.1 | 3.6 | 4.1 | 4.7 | 5.7 | 6.8 | 7.8 | 9.2 | 11.2 | 13.7 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 1.6 | 2 | 2.5 | 3 | 3.5 | 4 | 5 | 6 | 7 | 8 | 10 | 12 | |

| IBanga A | imiz | 1.46 | 1.86 | 2.36 | 2.86 | 3.32 | 3.82 | 4.82 | 5.82 | 6.78 | 7.78 | 9.78 | 11.73 | |

| IBanga B | imiz | 1.35 | 1.75 | 2.25 | 2.75 | 3.2 | 3.7 | 4.7 | 5.7 | 6.64 | 7.64 | 9.64 | 11.57 | |

| dw | IBanga A | imiz | 2.54 | 3.34 | 4.34 | 4.84 | 5.34 | 6.2 | 7.2 | 8.88 | 9.63 | 11.63 | 14.63 | 16.63 |

| IBanga B | imiz | 2.42 | 3.22 | 4.22 | 4.72 | 5.22 | 6.06 | 7.06 | 8.74 | 9.47 | 11.47 | 14.47 | 16.47 | |

| e | IBanga A | imiz | 3.41 | 4.32 | 5.45 | 6.01 | 6.58 | 7.66 | 8.79 | 11.05 | 12.12 | 14.38 | 17.77 | 20.03 |

| IBanga B | imiz | 3.28 | 4.18 | 5.31 | 5.88 | 6.44 | 7.5 | 8.63 | 10.89 | 11.94 | 14.2 | 17.59 | 19.85 | |

| L1 | max | 0.6 | 0.8 | 1 | 1 | 1 | 1.2 | 1.2 | 1.4 | 1.4 | 2 | 2 | 3 | |

| k | Ubungakanani bobizo | 1.1 | 1.4 | 1.7 | 2 | 2.4 | 2.8 | 3.5 | 4 | 4.8 | 5.3 | 6.4 | 7.5 | |

| IBanga A | max | 1.225 | 1.525 | 1.825 | 2.125 | 2.525 | 2.925 | 3.65 | 4.15 | 4.95 | 5.45 | 6.58 | 7.68 | |

| imiz | 0.975 | 1.275 | 1.575 | 1.875 | 2.275 | 2.675 | 3.35 | 3.85 | 4.65 | 5.15 | 6.22 | 7.32 | ||

| IBanga B | max | 1.3 | 1.6 | 1.9 | 2.2 | 2.6 | 3 | 3.74 | 4.24 | 5.04 | 5.54 | 6.69 | 7.79 | |

| imiz | 0.9 | 1.2 | 1.5 | 1.8 | 2.2 | 2.6 | 3.26 | 3.76 | 4.56 | 5.06 | 6.11 | 7.21 | ||

| k1 | IBanga A | imiz | 0.68 | 0.89 | 1.1 | 1.31 | 1.59 | 1.87 | 2.35 | 2.7 | 3.26 | 3.61 | 4.35 | 5.12 |

| IBanga B | imiz | 0.63 | 0.84 | 1.05 | 1.26 | 1.54 | 1.82 | 2.28 | 2.63 | 3.19 | 3.54 | 4.28 | 5.05 | |

| r | imiz | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.2 | 0.2 | 0.25 | 0.25 | 0.4 | 0.4 | 0.6 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 3.2 | 4 | 5 | 5.5 | 6 | 7 | 8 | 10 | 11 | 13 | 16 | 18 | |

| IBanga A | imiz | 3.02 | 3.82 | 4.82 | 5.32 | 5.82 | 6.78 | 7.78 | 9.78 | 10.73 | 12.73 | 15.73 | 17.73 | |

| IBanga B | imiz | 2.9 | 3.7 | 4.7 | 5.2 | 5.7 | 6.64 | 7.64 | 9.64 | 10.57 | 12.57 | 15.57 | 17.57 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Screw Thread | (M14) | M16 | (M18) | M20 | (M22) | M24 | (M27) | M30 | (M33) | M36 | (M39) | M42 | ||

| P | I-pitch | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | |

| b | L≤125 | 34 | 38 | 42 | 46 | 50 | 54 | 60 | 66 | 72 | - | - | - | |

| 125<L≤200 | 40 | 44 | 48 | 52 | 56 | 60 | 66 | 72 | 78 | 84 | 90 | 96 | ||

| L>200 | 53 | 57 | 61 | 65 | 69 | 73 | 79 | 85 | 91 | 97 | 103 | 109 | ||

| c | max | 0.6 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 1 | 1 | |

| imiz | 0.15 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | ||

| da | max | 15.7 | 17.7 | 20.2 | 22.4 | 24.4 | 26.4 | 30.4 | 33.4 | 36.4 | 39.4 | 42.4 | 45.6 | |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 14 | 16 | 18 | 20 | 22 | 24 | 27 | 30 | 33 | 36 | 39 | 42 | |

| IBanga A | imiz | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | - | - | - | - | - | - | |

| IBanga B | imiz | 13.57 | 15.57 | 17.57 | 19.48 | 21.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 38.38 | 41.38 | |

| dw | IBanga A | imiz | 19.64 | 22.49 | 25.34 | 28.19 | 31.71 | 33.61 | - | - | - | - | - | - |

| IBanga B | imiz | 19.15 | 22 | 24.85 | 27.7 | 31.35 | 33.25 | 38 | 42.75 | 46.55 | 51.11 | 55.86 | 59.95 | |

| e | IBanga A | imiz | 23.36 | 26.75 | 30.14 | 33.53 | 37.72 | 39.98 | - | - | - | - | - | - |

| IBanga B | imiz | 22.78 | 26.17 | 29.56 | 32.95 | 37.29 | 39.55 | 45.2 | 50.85 | 55.37 | 60.79 | 66.44 | 71.3 | |

| L1 | max | 3 | 3 | 3 | 4 | 4 | 4 | 6 | 6 | 6 | 6 | 6 | 8 | |

| k | Ubungakanani bobizo | 8.8 | 10 | 11.5 | 12.5 | 14 | 15 | 17 | 18.7 | 21 | 22.5 | 25 | 26 | |

| IBanga A | max | 8.98 | 10.18 | 11.715 | 12.715 | 14.215 | 15.215 | - | - | - | - | - | - | |

| imiz | 8.62 | 9.82 | 11.285 | 12.285 | 13.785 | 14.785 | - | - | - | - | - | - | ||

| IBanga B | max | 9.09 | 10.29 | 11.85 | 12.85 | 14.35 | 15.35 | 17.35 | 19.12 | 21.42 | 22.92 | 25.42 | 26.42 | |

| imiz | 8.51 | 9.71 | 11.15 | 12.15 | 13.65 | 14.65 | 16.65 | 18.28 | 20.58 | 22.08 | 24.58 | 25.58 | ||

| k1 | IBanga A | imiz | 6.03 | 6.87 | 7.9 | 8.6 | 9.65 | 10.35 | - | - | - | - | - | - |

| IBanga B | imiz | 5.96 | 6.8 | 7.81 | 8.51 | 9.56 | 10.26 | 11.66 | 12.8 | 14.41 | 15.46 | 17.21 | 17.91 | |

| r | imiz | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | 1 | 1 | 1 | 1 | 1 | 1.2 | |

| s | ubuninzi=ubungakanani obuqhelekileyo | 21 | 24 | 27 | 30 | 34 | 36 | 41 | 46 | 50 | 55 | 60 | 65 | |

| IBanga A | imiz | 20.67 | 23.67 | 26.67 | 29.67 | 33.38 | 35.38 | - | - | - | - | - | - | |

| IBanga B | imiz | 20.16 | 23.16 | 26.16 | 29.16 | 33 | 35 | 40 | 45 | 49 | 53.8 | 58.8 | 63.1 | |

| Ubude boMsonto b | - | - | - | - | - | - | - | - | - | - |

|

| ||

| Screw Thread | (M45) | M48 | (M52) | M56 | (M60) | M64 |

|

|

|

|

|

| ||

| P | I-pitch | 4.5 | 5 | 5 | 5.5 | 5.5 | 6 |

|

|

|

|

|

| |

| b | L≤125 | - | - | - | - | - | - |

|

|

|

|

|

| |

| 125<L≤200 | 102 | 108 | 116 | - | - | - |

|

|

|

|

|

| ||

| L>200 | 115 | 121 | 129 | 137 | 145 | 153 |

|

|

|

|

|

| ||

| c | max | 1 | 1 | 1 | 1 | 1 | 1 |

|

|

|

|

|

| |

| imiz | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

|

|

|

|

|

| ||

| da | max | 48.6 | 52.6 | 56.6 | 63 | 67 | 71 |

|

|

|

|

|

| |

| ds | ubuninzi=ubungakanani obuqhelekileyo | 45 | 48 | 52 | 56 | 60 | 64 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 44.38 | 47.38 | 51.26 | 55.26 | 59.26 | 63.26 |

|

|

|

|

|

| |

| dw | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 64.7 | 69.45 | 74.2 | 78.66 | 83.41 | 88.16 |

|

|

|

|

|

| |

| e | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 76.95 | 82.6 | 88.25 | 93.56 | 99.21 | 104.86 |

|

|

|

|

|

| |

| L1 | max | 8 | 10 | 10 | 12 | 12 | 13 |

|

|

|

|

|

| |

| k | Ubungakanani bobizo | 28 | 30 | 33 | 35 | 38 | 40 |

|

|

|

|

|

| |

| IBanga A | max | - | - | - | - | - | - |

|

|

|

|

|

| |

| imiz | - | - | - | - | - | - |

|

|

|

|

|

| ||

| IBanga B | max | 28.42 | 30.42 | 33.5 | 35.5 | 38.5 | 40.5 |

|

|

|

|

|

| |

| imiz | 27.58 | 29.58 | 32.5 | 34.5 | 37.5 | 39.5 |

|

|

|

|

|

| ||

| k1 | IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

|

| IBanga B | imiz | 19.31 | 20.71 | 22.75 | 24.15 | 26.25 | 27.65 |

|

|

|

|

|

| |

| r | imiz | 1.2 | 1.6 | 1.6 | 2 | 2 | 2 |

|

|

|

|

|

| |

| s | ubuninzi=ubungakanani obuqhelekileyo | 70 | 75 | 80 | 85 | 90 | 95 |

|

|

|

|

|

| |

| IBanga A | imiz | - | - | - | - | - | - |

|

|

|

|

|

| |

| IBanga B | imiz | 68.1 | 73.1 | 78.1 | 82.8 | 87.8 | 92.8 |

|

|

|

|

|

| |

| Ubude boMsonto b | - | - | - | - | - | - |

|

|

|

|

| |||

Iimpawu kunye neeNzuzo

ICarbon Steel Hex Bolt Din 931/iso4014 sisisombululo esikwizinga eliphezulu sokuqina esenziwe kwizinto ezithembekileyo zekhabhoni. Iza kunye nesakhiwo sentloko ye-hexagonal eyenzelwe ukuba ilungele ngokufanelekileyo i-wrench okanye i-socket, okwenza kube lula ukuqinisa okanye ukukhulula ngaphandle kokuphuma. Imigangatho ye-Din 931 kunye ne-iso4014 iqinisekisa ngakumbi ukuchaneka kwayo, ukuqina, kunye nokuthembeka kwayo kwizicelo ezahlukeneyo.

Olu hlobo lwe-hex bolt lune-shank enemisonto enemisonto engaphelelanga okanye ephothiweyo ngokupheleleyo evumela ukhuseleko kunye nokuqina okuqinileyo xa kudityaniswa izinto ezimbini okanye ngaphezulu. Iqhele ukusetyenziswa kwizicelo ezibandakanya oomatshini, izixhobo, kunye nezakhiwo ezifuna amandla aphezulu, ukhuseleko, kunye nolungelelwaniso oluchanekileyo.

Intsimbi yeCarbon, i-alloy yensimbi ene-ferrous eyenziwe ngokuyintloko yentsimbi kunye nekhabhoni, lolona khetho lubalaseleyo kolu hlobo lwebholiti ngenxa yamandla ayo, ukuqina, kunye nokuxhathisa ukunxiba kunye nokukrazula. Ngaloo ndlela, iCarbon Steel Hex Bolt Din 931/iso4014 inokumelana nemekobume erhabaxa, uxinzelelo oluphezulu, kunye namaqondo obushushu aphezulu ngaphandle kokuphulukana namandla ayo okuqina okanye ukubola. Kwakhona, beza ngeendlela ezahlukeneyo ezifana ne-oxide emnyama, i-galvanized, kunye ne-zinc yokukhusela kwi-corrosion.

Ukuguquguquka kunye nokuthembeka kweCarbon Steel Hex Bolt Din 931 / iso4014 yenza enye yezona zibophelelo ezidumileyo kwishishini. Ifumaneka ngobukhulu obahlukeneyo ukulungiselela iimfuno ezahlukeneyo zesicelo, kwaye imilo ye-hexagonal iqinisekisa ukufakela kunye nokususwa ngokulula. Nokuba usebenza kwiprojekthi yoshishino, usetyenziso lweemoto, okanye ukuphuculwa kwekhaya, le hex bolt lukhetho oluthembekileyo.

Ukuqukumbela, iCarbon Steel Hex Bolt Din 931/iso4014 yinxalenye ebalulekileyo yalo naluphi na ulwakhiwo, ukuvelisa, okanye ukulungisa iiprojekthi ezifuna isibophelelo esinamandla, esikhuselekileyo nesithembekileyo. Amandla ayo abalaseleyo, ukuqina, kunye nokumelana nomhlwa kuyenza ibe lolona khetho lufanelekileyo kwizicelo ezahlukeneyo. Ke, ungathandabuzi ukukhetha le hex bolt kwiprojekthi yakho.